BUSINESS FIELD

BUSINESS FIELD

Mechanical Engineering

We provide total engineering services for special devices, test facilities, and plant equipment required by the industry by combining high-performance control valves and technologies.

Scope of Business

Design and manufacture of specialized equipment and plant designs for industry using high-tech valves and technologies

Design and manufacture of methanol-reformed hydrogen production plants

Incorporating high-performance control valves and technologies

Core Values

Hydrogen field of the 4th Industrial Revolution → Technology development and product market expansion

Large plant engineering technology

Application of technology possessing high-temperature and high-pressure fluid facility design → High temperature: 400℃, high-pressure: 200 bar → Design of various fluid facilities (tanks, heat exchangers, pumps, valves, etc.)

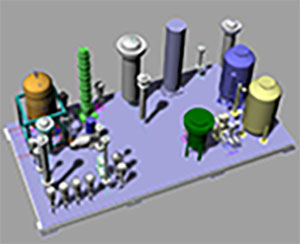

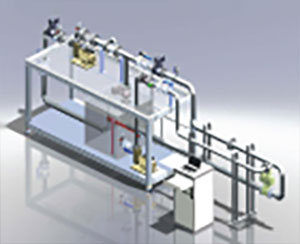

Methanol reformed hydrogen production plants

The plant is a hydrogen production plant using high-temperature and high-pressure thermal fluids and chemical processes, and its technology is to replace the hydrogen required for fuel cell modules from the hydrogen storage method (metal hydride storage alloy method) to the hydrogen production method (fuel reforming method).

Design Pressure : 100 kg/㎠

Fuel used : Methanol

Design temperature : 800 ℃

Process fluid: Water : Water, steam, gas

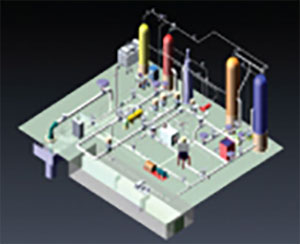

Performance Test Facility for High Temperature and Pressure Valves and Pumps

This facility is developed to test the performance of the valves and pumps for high temperature and pressure serviced in NSSS and BOP of nuclear power plant, and is designed in accordance with the requirements of KEPIC MF, ASME QME-1 and PTC code.

Design Pressure : 300 kg/㎠

Design Temperature : 371 ℃

Service Pressure : 207 kgf/㎠

Uncertainty : less than ±1%

Service Temperature : 300 ℃

Design Flowrate : 106 ㎥/min

Fluid Used : Water, Nitrogen

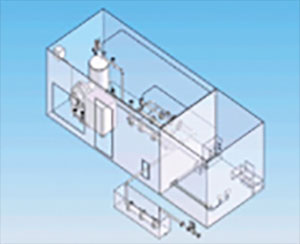

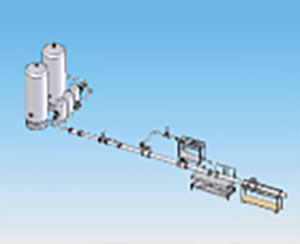

Performance Test Facility for High Temperature and Pressure Valves

This facility is developed to measure the leak rate of valve by sing ultrasonic wave and temperature change and by generating high temperature and pressure steam.

Design Pressure : 130 kg/㎠

Design Temperature : 340 ℃

Service Pressure : 110 kgf/㎠

Service Temperature : 300 ℃

Design Flowrate : 0.4 ㎥/min

Fluid Used : Water, Nitrogen

Performance Test Facility for Pressurizer Safety Valve

This facility is used to verify the opening set point, working fluid volume, and dynamic characteristic of loop seal and makes it possible to optimize the opening set point.

Design Pressure : 220 kg/㎠

Design Temperature : 380 ℃

Service Pressure : 220 kgf/㎠

Uncertainty: less than : less than ±1%

Service Temperature : 380 ℃

Design Flowrate : 420,000 lb/hr

Uncertainty: : Water, Nitrogen

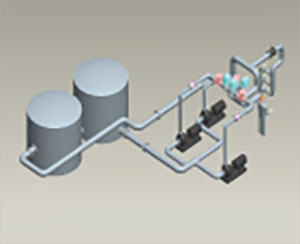

Water Hammer Generating Facility

This facility simulates a water hammer condition occurring when flowing fluid inside pipe is blocked abruptly and evaluates the power of water hammer by adjusting flow direction and pressure. The water hammer usually is accompanied with noise and vibration and may damage the equipments and instruments equipped with piping.

Design Pressure : 12kgf/㎠

Design Temperature : 100 ℃

Design Flow Rate: : 40㎥/hr

Fluid Used : Water

Low Temperature Performance Test Facility for Valves

This facility is used to test and diagnose the performance of precise control valve and actuator, measures the control power of flowrate and displacement including Cv. The analysis of test results indicates necessity of maintenance.

Design Pressure : 15kgf/㎠

Uncertainty : less than ±1%

Fluid Used : Water

Valve Performance Test Facility Using Air

This facility is used to test and diagnose the performance of precise control valve, and measures the differential pressure, flow rate, control power. The measured results are compared with design valves to diagnose the performance of control valve.

Design Pressure : 9kgf/㎠

Aux. Pipe : 3″, ANSI class 300

Main Pipe : 8″, ANSI class 300

R&D Center : #201, Hoban Plaza, Jijok-ro 351, Yuseong-gu, Daejeon

R&D Center : #201, Hoban Plaza, Jijok-ro 351, Yuseong-gu, Daejeon